Waterproofing

Waterproofing

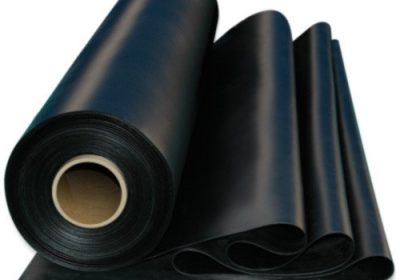

EPDM

It is a Rubber sheet is supplied in rolls. EPDM has been used throughout the USA and Canada for the past 40 years. The life expectancy of EPDM rubber is 20+ years.

EPDM is installed in an exceptionally more eco-friendly way, without the lengthy and dangerous use of heat and flames. Combined with these properties are the facts that the EPDM rubber sheet provides excellent thermal properties and is an outstanding sealant against water penetration. It’s no wonder EPDM rubber is also used extensively in many other industries.

Cold Applied

Bitumen-based waterproofing is a process that involves spraying a layer of bituminous coating on pavements and other surfaces that may be prone to water damage. The bituminous coat, once dry, creates a protective layer on the surface and prevents water from seeping into the pavement and other materials. In turn, the surface remains protected from any water damage that may affect its quality.

APP Membrane

APP-Modified Bitumen is a plastic bitumen blend, which is modified using plastic in the form of atactic polypropylene (APP).

APP has a high-temperature tolerance when heating, so is more user-friendly for installers.

It is used in curtain walls, foundations, and projects with high tensile requirements, basement walls, balconies, terrace roofs, inclined roofs, water tanks, manmade ponds, retaining walls, concrete channels as well as bathrooms and any wet surfaces.

10 cm overtopping shall be allowed for joints and 15 cm overtopping for ends by using a welding torch.

The surface coated with mineral stone on the joints should be heated and minerals should be buried into the bituminous surface by using a trowel before welding the joints together.

The transverse joints of the first layer covering should be laid down in an offset position.

SBS Membrane

Styrene-Butadiene-Styrene (SBS) describes a family of synthetic rubber derived from styrene and butadiene.

SBS is a thermo-plastic elastomer that has excellent abrasion resistance and aging stability when blended with bitumen, making it the perfect bitumen modifier to achieve cold flexibility and elastic properties.

This material has the ability to retain its shape after being stretched and therefore, is widely used in modified bitumen roofing, coatings, sealants, and paving amongst other applications.

Compatibility with all types of flat roofing applications, but can also be used to waterproof car park decks, bridge decks, green roofs, etc.

Resistance to the most extreme weather conditions such as high and low temperatures, rain, snow, ice, and the freeze-thaw process.

High resistance to mechanical damage and puncturing in comparison to alternative flat roof coverings. Extreme resistance variants are available depending on the traffic requirements of the surface.

PVC Membrane

PVC or polyvinyl chloride roofing systems are one of the most popular options for flat or low-sloped roofs Or Landscapes. PVC, short for polyvinyl chloride, is a single-ply roofing membrane that is known for its longevity, durability, and energy efficiency. They’re also highly resistant to some of the toughest flat roof aggressors like fire, chemicals, and hurricane-level winds.

PVC roofing membrane is a single-ply membrane composed of two layers of polyvinyl chloride where polyester is added in between to act as reinforcement. Polyester reinforcement is added to achieve high tearing and breaking strengths necessary for mechanically fastened single-ply roofing systems.