Industrial Flooring

Industrial Flooring

Steel Fiber Concrete

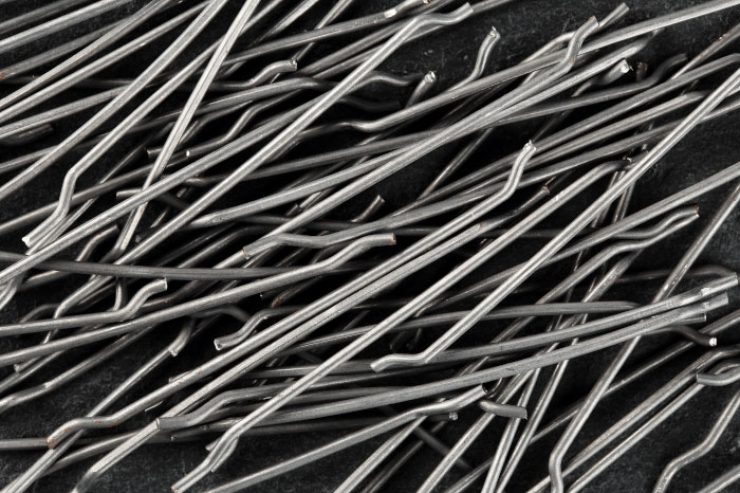

Steel Fiber Concrete is a type of reinforcement concrete. Steel fiber reinforced concrete (SFRC) as the name suggests is made up of composite materials such as cement, sand, aggregate, water, gravel, steel fiber, and admixture. In this concrete fiber, steel fiber is an additional ingredient.

Fiber added into the concrete is 0.3 to 2.5% by its volume of plain cement concrete. The diameter of steel fiber used in concrete is 0.25 mm to 0.75 mm. A common round shape of steel fiber is used.

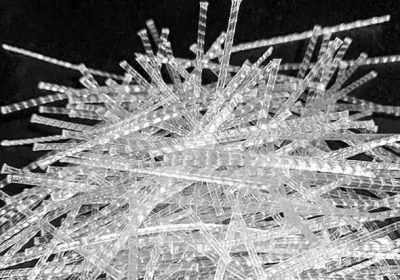

Macro Fiber Concrete

Synthetic fiber-reinforced concrete can be defined as concrete that incorporates macro fibers. The main reasons for using fibers such as the macro-synthetic fibers in concrete are to replace the traditional steel rebar reinforcement and enhance its flexural performance, resist crack formation due to drying shrinkage or temperature movement, increase toughness, durability, water-tightness and overall performance of concrete.

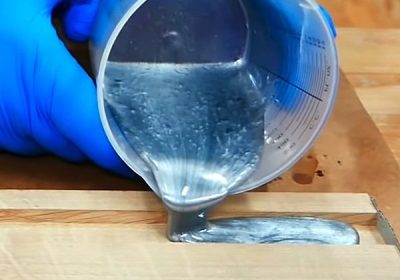

Epoxy

They are based on a combination of resins and hardeners. When mixed together, the resin and hardener chemically react to form a rigid plastic material. The final material is strong, durable, resistant, and bonds extremely well to most base layers. Epoxy floors are so that they’re often used in heavy-traffic areas such as industrial environments, hospitals, or sports facilities.

The most reliable and economical choice when it comes to a high-quality floor finish. Because Polyurethane floor finish is better able to resist scratch, impact, and abrasion, it is still a valuable Choice when considering which floor coating to use In your organization. The most advantage of polyurethane is that it is UV stable.